Aluminum Automatic Machine Customized

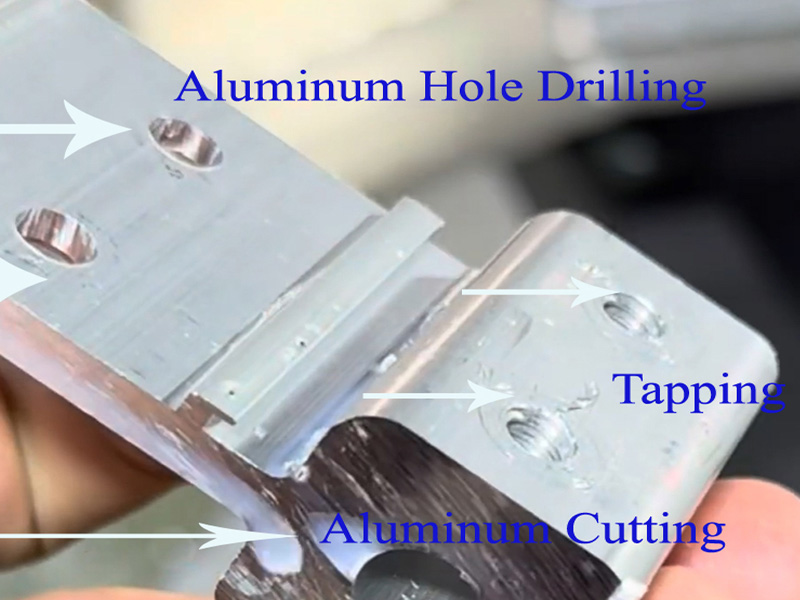

Hole drillilng

Hole chamfering

Hole tapping

Cutting

In the current industrial manufacturing field, efficiency and accuracy have become the core requirements of customers for equipment. To meet the increasingly complex and diverse production needs of customers for aluminum profile processing, our company has recently developed an automatic aluminum processing machine that integrates drilling, chamfering, drilling, and cutting. The equipment has been successfully delivered and officially put into use.

Multi functional integration to meet complex machining processes

Unlike traditional single function processing equipment, the customized aluminum automatic processing machine has the following four core functions:

Precision drilling: The equipment is equipped with high-precision servo controlled drilling units, which can quickly drill holes at any position on aluminum profiles, with a repeat positioning accuracy of up to ± 0.05mm, meeting the production requirements of multiple specifications and angles of hole positions.

Automatic chamfering: After drilling is completed, the chamfering blade automatically follows up to handle the burrs on the hole edge, achieving a smooth and even inner hole edge, effectively improving the product's aesthetics and assembly smoothness.

High speed drilling: For aluminum profiles that require special-shaped holes or large-diameter processes, the equipment supports CNC program settings to quickly complete precision drilling. Not only is the size stable, but the machining surface is also clean and deformation free.

Intelligent cutting: Using industrial grade sawing units and automatic feeding systems, precise cutting to length is achieved, with no burrs or deformations in the incision. The cutting speed and angle can be flexibly adjusted.

The four major functions work together on the same device platform, eliminating the need for multiple devices and processes to be repeatedly transported by customers, greatly improving processing efficiency and automation level.

Highly automated, simple and stable operation

In order to adapt to the production pace and personnel configuration of the customer's factory, the aluminum automatic processing machine has also undergone a comprehensive upgrade in automation control:

Full CNC operation interface: equipped with industrial touch screen and multilingual operating system, operators can easily set processing parameters through a graphical interface, supporting one click start and one click switch of process flow.

Intelligent workpiece recognition and positioning: Built in sensors automatically detect the size and placement position of aluminum materials, automatically adjust the machining track and tool movements, and ensure consistency in machining accuracy.

Automatic chip removal and lubrication system: The equipment is equipped with automatic chip removal and cooling lubrication modules, effectively extending tool life and maintaining a clean working environment.

Remote monitoring and fault diagnosis function: supports networked remote viewing of operating status, data statistics, and fault alarms, achieving digital equipment management.

After trial operation, the customer stated that the equipment far exceeded expectations in terms of accuracy, stability, and ease of operation. The equipment runs smoothly and is easy to maintain, which has significantly improved its overall production capacity.

Highly praised by the customer, further cooperation is imminent

After the equipment was delivered for use, the customer highly praised our company's technical strength and service quality: "This automatic processing machine perfectly solved our previous problems of scattered multiple processes and frequent manual intervention. The overall production efficiency has been improved by more than 50%, and the workload of employees has also been significantly reduced. We look forward to continuing to deepen cooperation with your company in more automation fields

In the future, our company will continue to focus on the automation application needs of industries such as aluminum, steel structure, furniture, and new energy. We will explore the construction of multifunctional integrated equipment, high-efficiency production lines, and digital factories, and provide our customers with more professional and reliable customized solutions.