Core Features

Highly Customizable Adaptability: Supports precise customization of processing parameters according to customer needs, covering personalized requirements such as aluminum corner bracket thickness (1.5mm-5mm), hole size specifications (M4-M12), cutting length (20mm-100mm), thread pitch, and special-shaped structures. No additional equipment modification is required, enabling "one machine for multiple specifications" flexible production.

Integrated Drilling-Tapping-Cutting Function: The three core processes are integrated into one design. Full-process processing can be completed with a single material feeding, eliminating the need for manual process switching or material transfer. The processes are seamlessly connected, and the processing efficiency is 3-5 times higher than that of traditional equipment, significantly reducing manual intervention and process losses.

High-Precision Stable Output: Equipped with a numerical control system, the positioning accuracy reaches ±0.01mm, the drilling hole diameter error is ≤0.02mm, the tapped threads are smooth without burrs, and the cutting end face is flat without warping. The defect rate is controlled below 0.1%, meeting the requirements of precision assembly scenarios.

Easy Operation & Quick Mastery: Equipped with a visual touch interface, parameter setting is intuitive and easy to understand. It supports storage and retrieval of order parameters (up to 100+ sets of processing plans can be preset). New operators can operate independently after 1-2 hours of training, reducing reliance on professional technicians.

Industrial-Grade Durable Design: The machine body is made of high-strength steel through welding. Core components (motor, guide rail, cutting tool) are selected from high-quality brand accessories. It supports 24-hour continuous operation, adapts to high-intensity production scenarios, and the service life of the equipment is as long as 8-10 years.

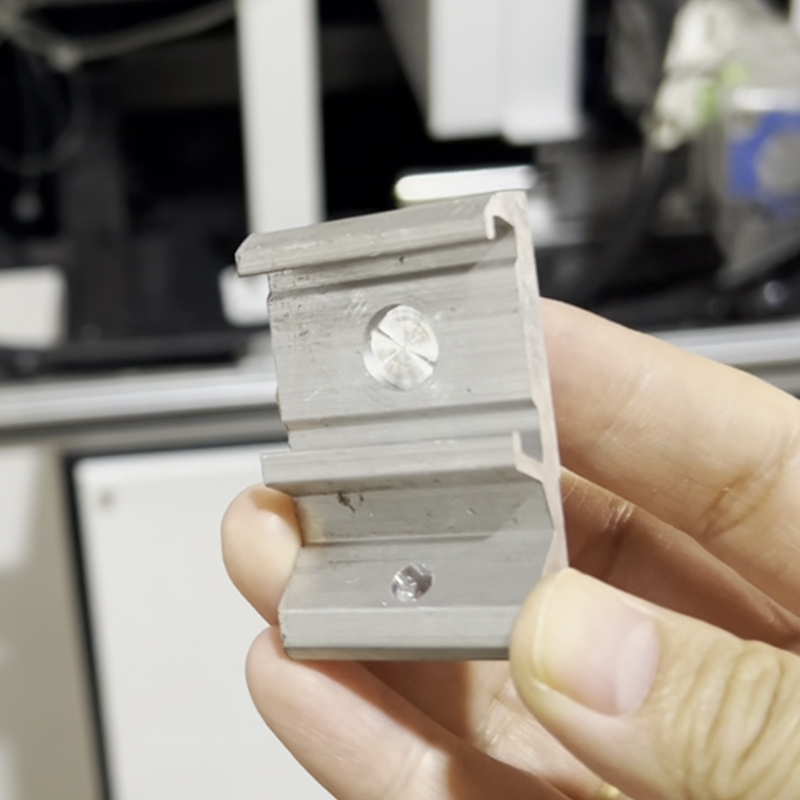

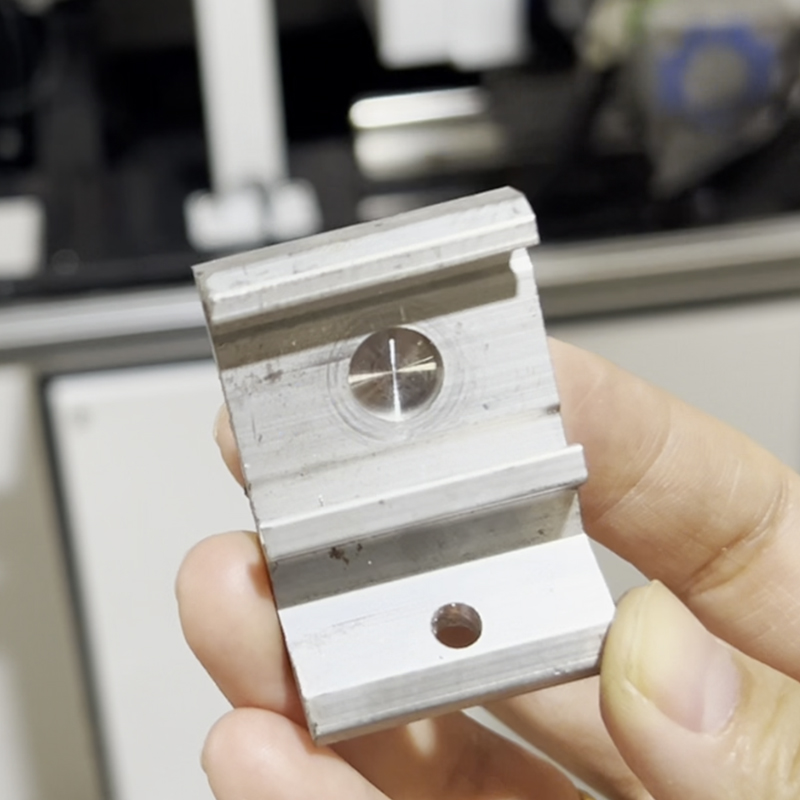

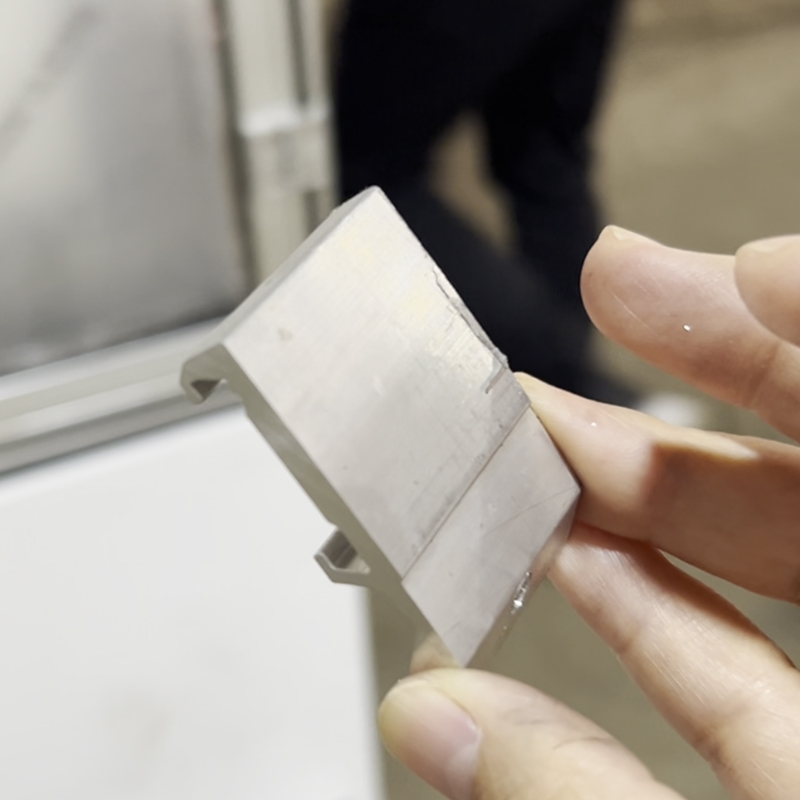

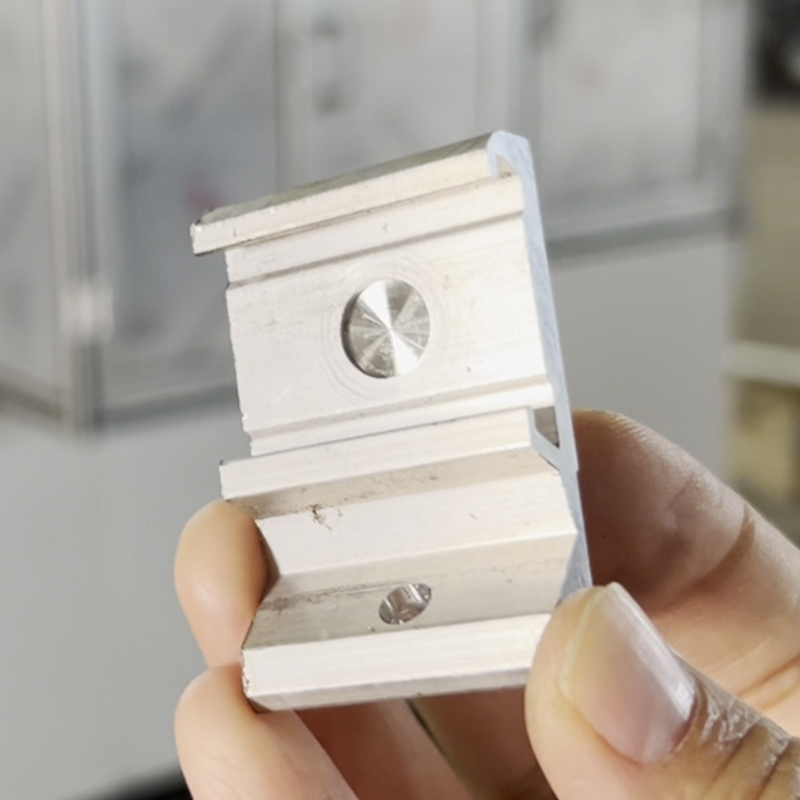

Aluminum Corners Automatic Machine Sample Display

Applicable Application Scenarios

Construction Door & Window Industry: Processing of corner connectors for products such as aluminum alloy casement windows, sliding windows, and broken-bridge aluminum windows, adapting to different profile thicknesses and assembly gap requirements.

Curtain Wall Engineering Field: Processing of keel connectors for glass curtain walls and aluminum panel curtain walls, meeting the high requirements for connector strength and precision in large-span structures.

Furniture Manufacturing Industry: Processing of splicing connectors for aluminum alloy furniture (wardrobes, cabinets, bookshelves), supporting customization of special-shaped corner brackets and hidden connectors.

Industrial Aluminum Profile Processing: Processing of corner fixing parts for industrial aluminum profiles such as automated equipment frames and conveyor line supports, adapting to the combination needs of multi-specification aluminum profiles.

Decoration & Renovation Field: Processing of supporting connectors for products such as aluminum alloy baseboards, ceiling keels, and decorative lines, meeting the size requirements of personalized decoration styles.

Usmart-Your Aluminum Automatic Machine Customized Expert, Contact Us Today:

WhatsApp/Wechat:+86-19819888691 WA:https://wa.me/8619819888691

Email:info@usmartcnc.com Website: https://www.usmartcnc.com

Youtube:https://www.youtube.com/@usmartaluminummachine

Tiktok:https://www.tiktok.com/@aluminummachine

Facebook:https://www.facebook.com/profile.php?id=61582053957512