In the wave of the door and window manufacturing industry moving towards intelligence and high efficiency, the upgrading and iteration of processing equipment have become the core driving force for improving production capacity and quality. As a key hardware accessory for opening and closing doors and windows, the processing accuracy of the installation part of door and window hinges directly determines the sealing performance, service life and safety factor of doors and windows. Under the traditional manual or semi-automatic processing mode, processes such as slotting, cutting and drilling are carried out separately, which not only leads to low efficiency, but also makes it difficult to ensure the consistency of processing accuracy. The emergence of automatic door and window hinge machines integrates slotting, cutting, 3 through-hole drilling and 3 counterbore processing into one, which has completely innovated the hinge processing process and injected new vitality into the door and window manufacturing industry.

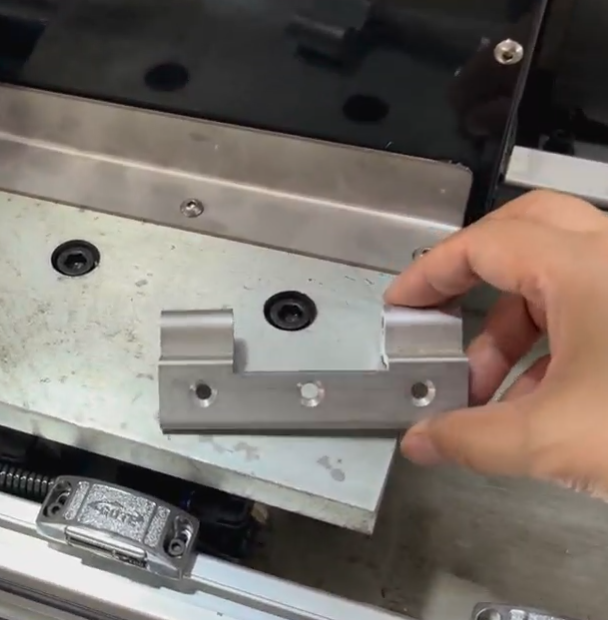

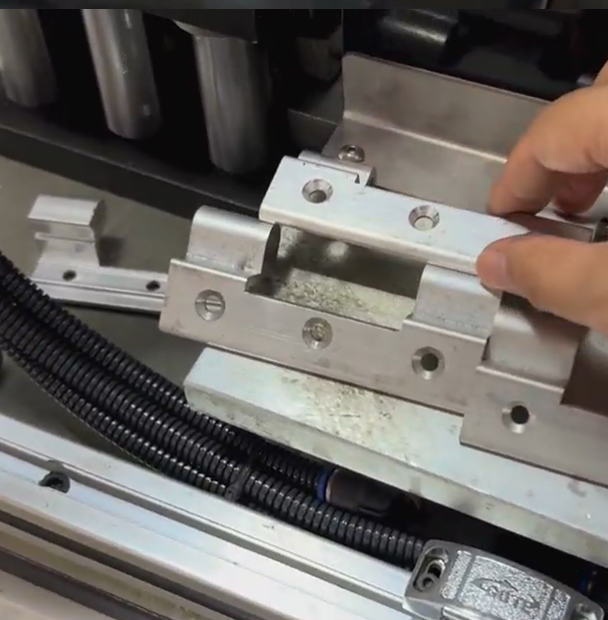

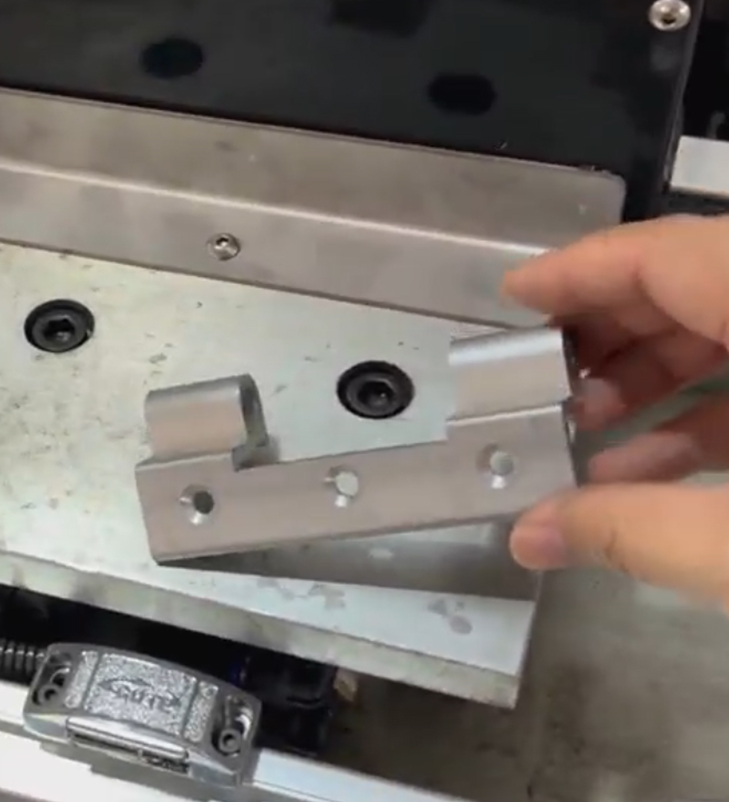

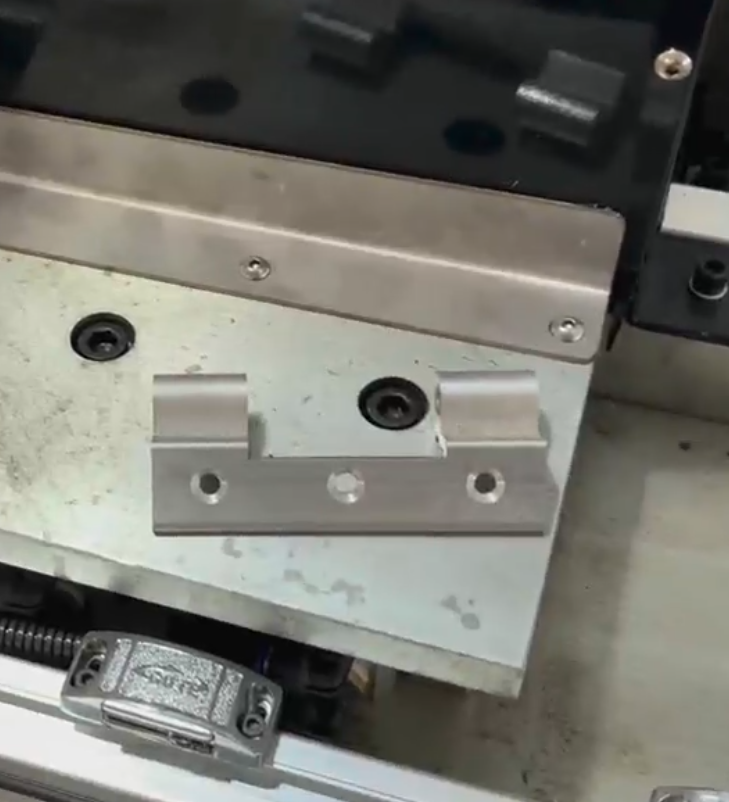

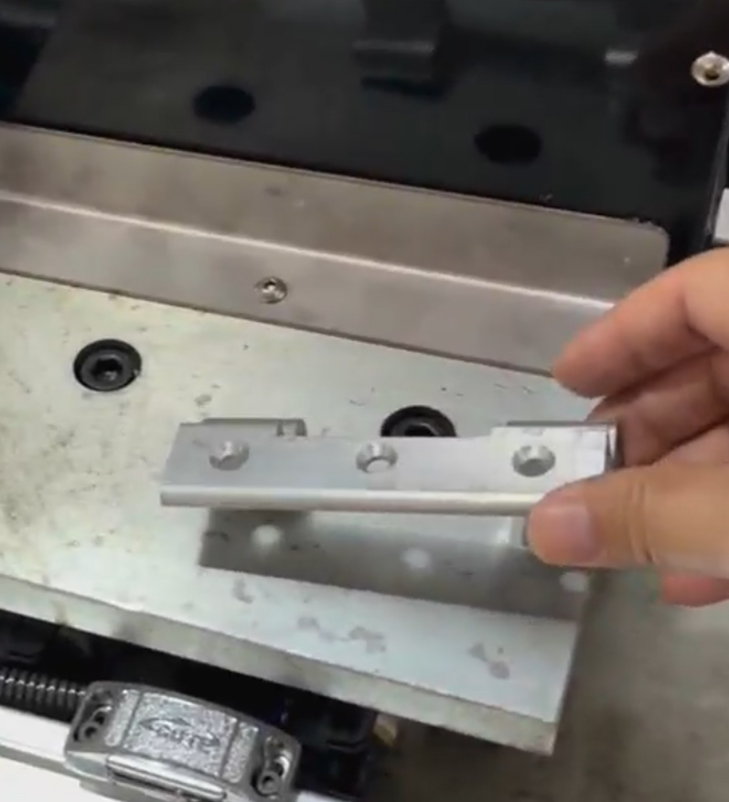

Aluminum Hinge Making Machine Sample Display

Drilling and countersinking are crucial steps in ensuring a secure hinge installation. Three through holes are used to secure the hinge bolts, while three countersinks accommodate the bolt heads, ensuring a smooth hinge surface. The automatic door and window hinge machine employs a multi-axis linkage drilling system, simultaneously machining three through holes and three countersinks without requiring multiple positioning switches. The equipment precisely controls the drilling depth and countersink angle using preset processing parameters, ensuring the coaxiality of the through holes and countersinks and preventing bolts from failing to install or becoming loose after installation. Furthermore, the equipment is equipped with an automatic chip removal system that cleans up metal or wood chips in real time during processing, maintaining a clean processing environment and preventing chips from affecting processing accuracy.

Compared to traditional processing equipment, the core advantages of automatic door and window hinge machines lie in their "integrated design" and "high-precision control." In traditional processing, operators need to frequently change equipment and adjust workpiece positioning. Drilling and countersinking alone may require two positioning calibrations, which is not only time-consuming and labor-intensive but also prone to problems such as misaligned hinge installation and jamming of doors and windows due to positioning deviations. Automatic machines, through precise mechanical structure design and intelligent control systems, achieve full automation from workpiece loading and positioning clamping to grooving, cutting, drilling, and countersinking. The high-precision servo motor and ball screw transmission system equipped with the machine can control processing errors within millimeters, ensuring that the grooving depth, cutting size, drilling position, and countersinking angle of each workpiece are completely uniform, fundamentally solving the precision problem of traditional processing.

Aluminum Hinge Making Machine Sample Display

Usmart-Your Aluminum Automatic Machine Customized Expert, Contact Us Today:

WhatsApp/Wechat:+86-19819888691 WA:https://wa.me/8619819888691

Email:info@usmartcnc.com Website: https://www.usmartcnc.com

Youtube:https://www.youtube.com/@usmartaluminummachine

Tiktok:https://www.tiktok.com/@aluminummachine

Facebook:https://www.facebook.com/profile.php?id=61582053957512