What Is a Solar Photovoltaic Aluminum Machine?

At its core, a Solar Photovoltaic Aluminum Machine refers to a series of specialized processing equipment designed to shape, cut, drill, and assemble aluminum alloys into PV-specific structural parts. Unlike general-purpose aluminum processing machines, this equipment is tailored to the unique requirements of solar systems: high dimensional accuracy (to ensure panel alignment), corrosion resistance (to withstand rain, UV rays, and temperature fluctuations), and compatibility with PV mounting designs (such as ground-mounted racks, rooftop brackets, and tracker systems).

Common types of PV aluminum machines include:

Aluminum extrusion machines: Convert aluminum ingots into long, customized profiles (e.g., U-shaped frames for solar panels, T-shaped support beams) through high-pressure extrusion, the foundational step in PV aluminum component production.

Precision cutting machines: Use CNC (Computer Numerical Control) technology to cut extruded aluminum profiles into exact lengths (often within a tolerance of ±0.1mm), ensuring consistency across large batches of PV frames.

Drilling and tapping machines: Create precise holes and threaded openings in aluminum profiles for bolted connections—critical for assembling PV mounting structures that must withstand wind loads and seismic activity.

Surface treatment machines: Apply anti-corrosion coatings (such as anodization or powder coating) to aluminum parts, extending their lifespan from 5–10 years to over 25 years—matching the typical service life of solar panels.

Aluminum Photovoltaic Hole Drilling and Cutting Automatic Machine

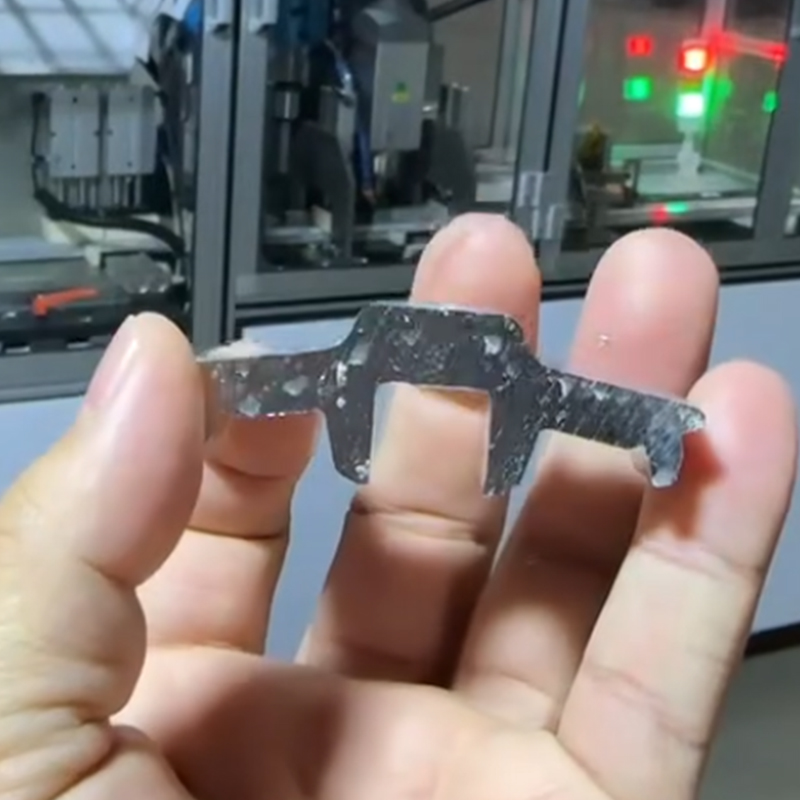

Sample Display

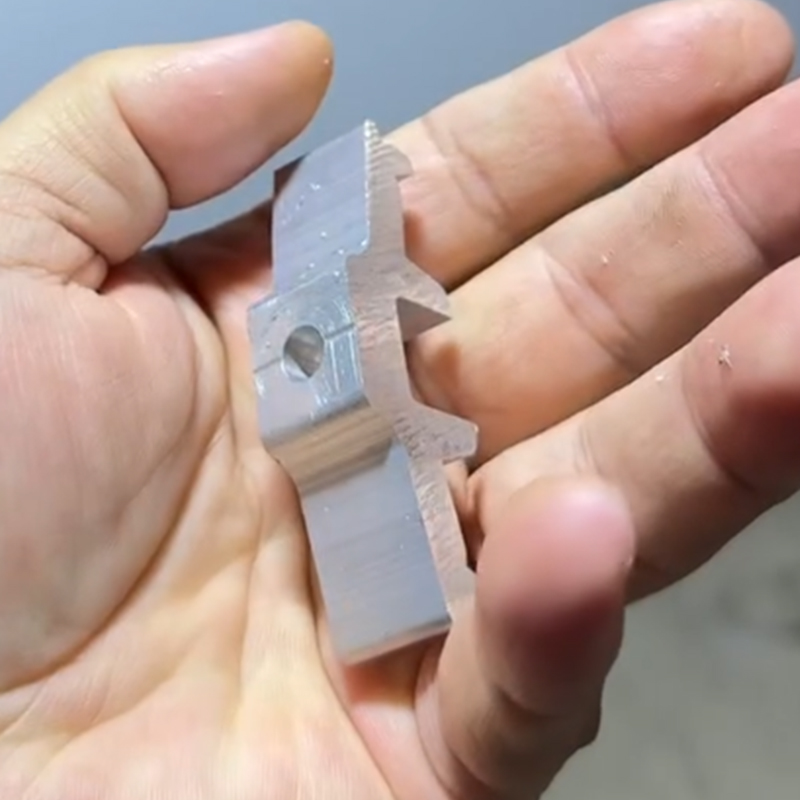

Sample Display

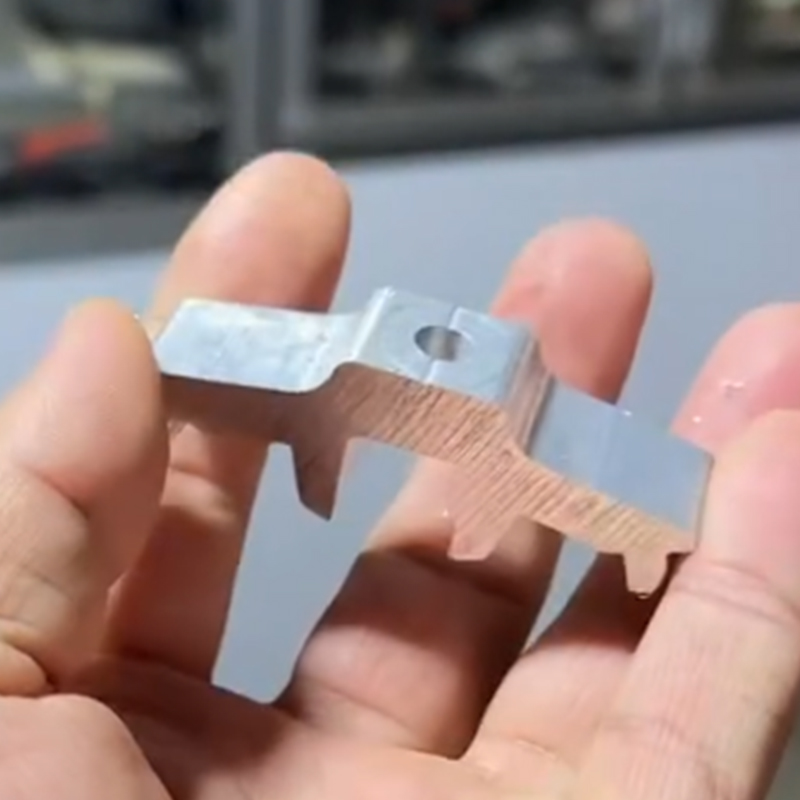

Sample Display

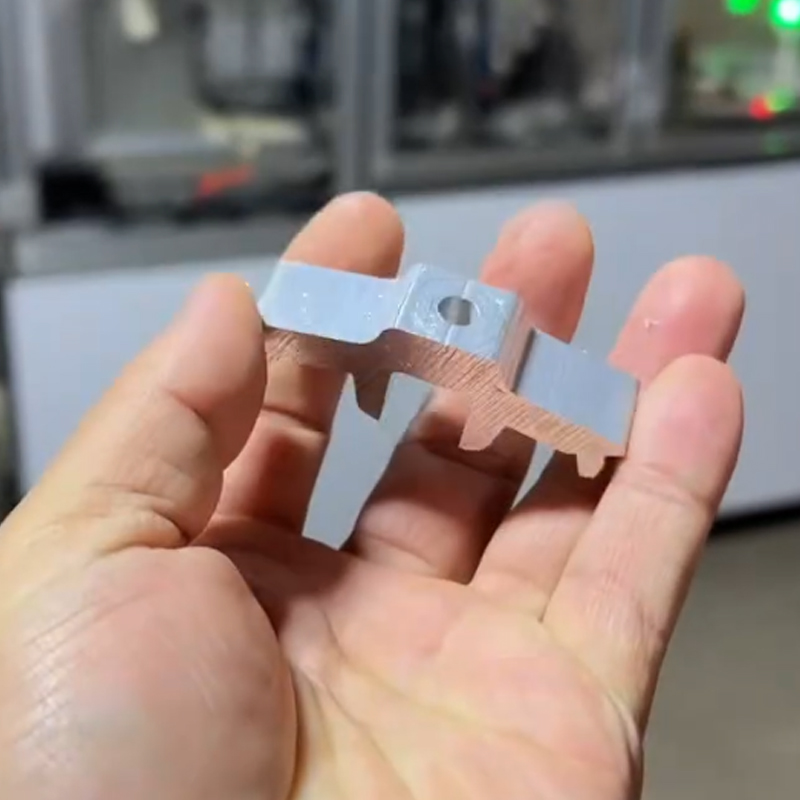

Sample Display

Why the PV Industry Relies on Specialized Aluminum Processing Machines

Aluminum is the material of choice for PV structures due to its lightweight (one-third the density of steel), high strength-to-weight ratio, and natural resistance to rust. However, translating these advantages into functional PV components requires equipment that meets the industry’s rigorous standards—and this is where PV-specific aluminum machines excel.

1.Meeting the Precision Demands of PV Systems

Solar panels must be installed in perfectly aligned arrays to maximize sunlight absorption; even minor deviations in frame size or hole positioning can reduce energy output. PV aluminum machines use CNC technology and automated calibration systems to achieve dimensional accuracy within 0.05mm, far exceeding the tolerance of general aluminum processing equipment. For example, a CNC cutting machine for PV frames can process 50–100 profiles per hour while maintaining consistent length, ensuring that every panel fits seamlessly into the mounting structure.

2. Enhancing Durability for Outdoor Environments

PV systems operate outdoors for decades, exposed to extreme weather—from scorching desert heat to coastal salt spray. Solar Photovoltaic Aluminum Machines address this by integrating advanced surface treatment processes: anodization machines create a 10–20μm thick oxide layer on aluminum surfaces, while powder coating machines apply a UV-resistant polymer layer. These treatments prevent aluminum corrosion and fading, ensuring that PV structures remain stable even in harsh climates. A study by the International Energy Agency (IEA) found that PV systems using machine-processed, coated aluminum frames had a 30% lower failure rate than those using unprocessed aluminum over a 20-year period.

3. Scaling Production for Global PV Growth

The global PV market is expanding at a compound annual growth rate (CAGR) of 15–20%, driven by falling costs and policy support for clean energy. PV aluminum machines are designed for high-volume production: a modern extrusion line can produce 1,000–2,000 meters of PV aluminum profiles per day, while automated assembly lines integrate cutting, drilling, and coating into a single workflow, reducing production time by 40% compared to manual processing. This scalability is critical for meeting the demand of large-scale PV projects, such as China's 100GW annual solar capacity additions or the EU's Green Deal targets.

Usmart-Your Aluminum Automatic Machine Customized Expert, Contact Us Today:

WhatsApp/Wechat:+86-19819888691 WA:https://wa.me/8619819888691

Email:info@usmartcnc.com Website: https://www.usmartcnc.com

Youtube:https://www.youtube.com/@usmartaluminummachine

Tiktok:https://www.tiktok.com/@aluminummachine