Driven by the global "dual-carbon" goals, solar photovoltaic (PV) energy, as a clean and sustainable energy source, is experiencing explosive growth. From large-scale ground-mounted PV power plants to distributed rooftop PV systems, the efficient operation of every PV power plant is underpinned by a variety of core materials. Among these, aluminum profiles, leveraging their multiple advantages such as lightweight, corrosion resistance, ease of processing, and recyclability, have become an indispensable "invisible framework" for the PV industry. They are widely used in key components like PV mounting structures, module frames, and inverter enclosures, providing solid guarantees for the stability, cost-effectiveness, and long service life of PV systems.

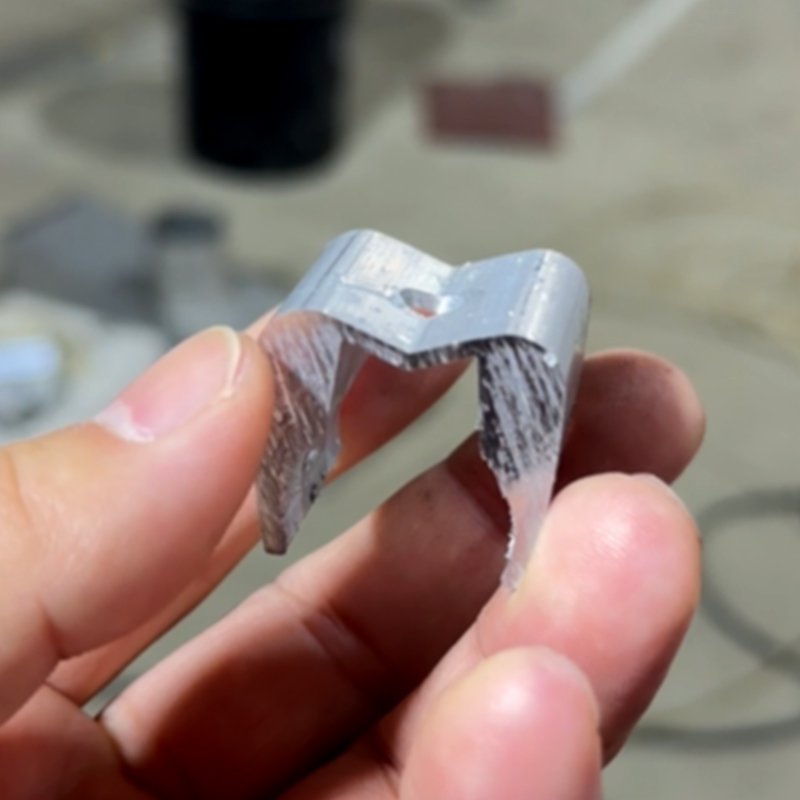

Aluminum PV hole drilling is not ordinary metal drilling; it requires targeted solutions to challenges posed by aluminum's material properties and the special needs of PV systems:

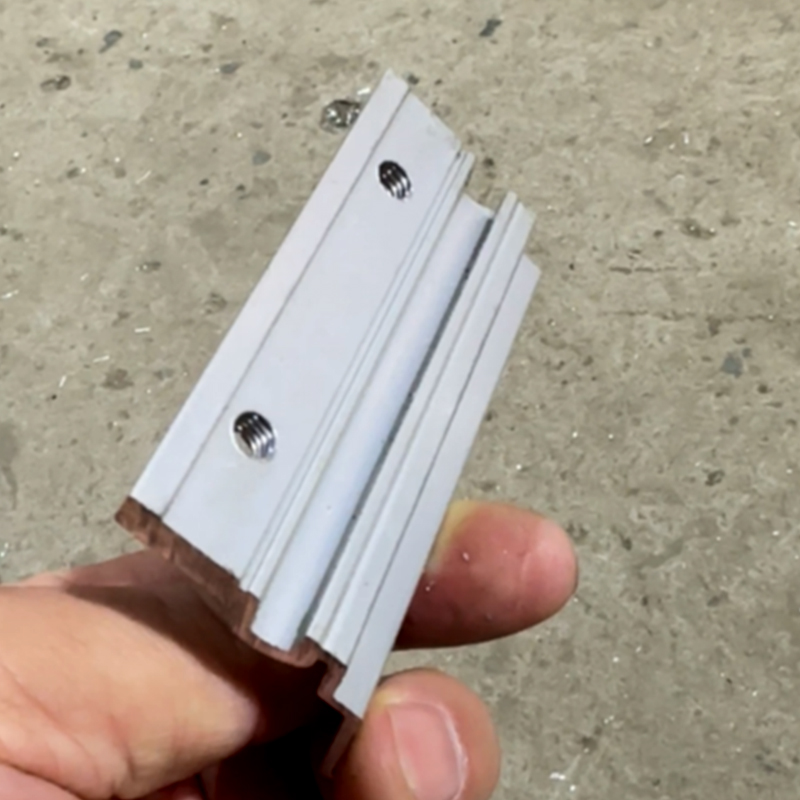

Aluminum Photovoltaic(PV)Automatic Machine

Future Outlook: How Will Aluminum Profiles Adapt to the Future Development of the PV Industry?

As the PV industry moves toward "higher efficiency, lower costs, and broader application scenarios," aluminum profiles are also continuously upgrading to meet new demands:

1.High-Strength and Thin-Walled Development

By optimizing alloy compositions (e.g., adding scandium elements) and heat treatment processes, high-strength aluminum profiles are being developed (with a tensile strength of ≥400MPa). At the same time, the wall thickness of frames and supports is reduced from 1.2mm to 0.8mm, further reducing weight and material costs.

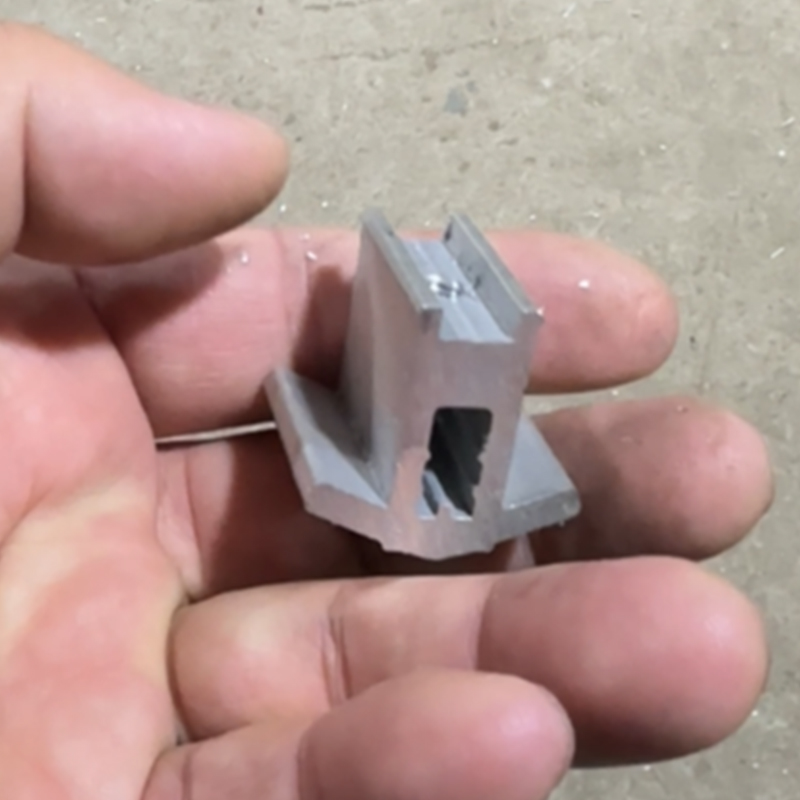

2.Integrated Design

Integrating PV supports with frames and inverter enclosures, "integrated aluminum profile structures" are being developed to reduce the number of components and improve system integration. For example, the "support-frame" integrated design for rooftop PV systems can reduce fasteners by 50% and increase installation efficiency by 50%.

3.Green Recycling

The recycling rate of aluminum is over 95%, and the energy consumption of the recycling process is only 5% of that required for primary aluminum production. In the future, the PV industry will promote the "recycling and reuse of decommissioned aluminum profiles" — for instance, recycling decommissioned PV supports and re-extruding them into new aluminum profiles to achieve "full-lifecycle green development."

Aluminum Photovoltaic(PV)Automatic Machine

Usmart-Your Aluminum Automatic Machine Customized Expert, Contact Us Today:

WhatsApp/Wechat:+86-19819888691 WA:https://wa.me/8619819888691

Email:info@usmartcnc.com Website: https://www.usmartcnc.com

Youtube:https://www.youtube.com/@usmartaluminummachine

Tiktok:https://www.tiktok.com/@aluminummachine