Customized non-standard automation equipment for Russian customers, efficiently empowering power line clamps and photovoltaic product processing

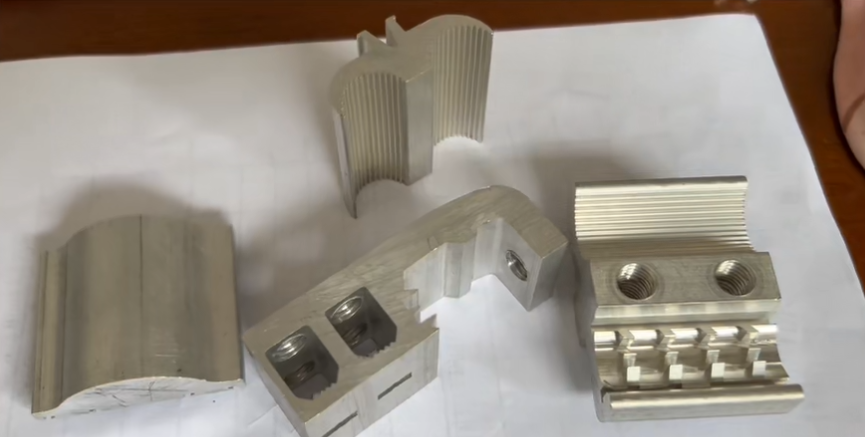

Recently, our company has successfully customized a non-standard automation equipment for power line clamps and photovoltaic accessory processing for Russian customers. This equipment integrates multiple key processes such as drilling, tapping, punching, and slotting, which not only greatly improves processing efficiency, but also effectively ensures the accuracy and consistency of products, and has been highly praised by customers.

Accurately meeting customer needs and showcasing non-standard design capabilities

The customer from Russia has been engaged in the manufacturing of power hardware and photovoltaic bracket products for a long time, and their products have high requirements for processing accuracy, structural strength, and production efficiency. The customer hopes to replace traditional manual or split processing modes with an automated solution to enhance overall production capacity and quality control capabilities.

After a detailed understanding of the customer's product structure and process flow, our sales and technical team organized multiple rounds of video conferences and solution discussions to customize and develop a set of solutions covering:

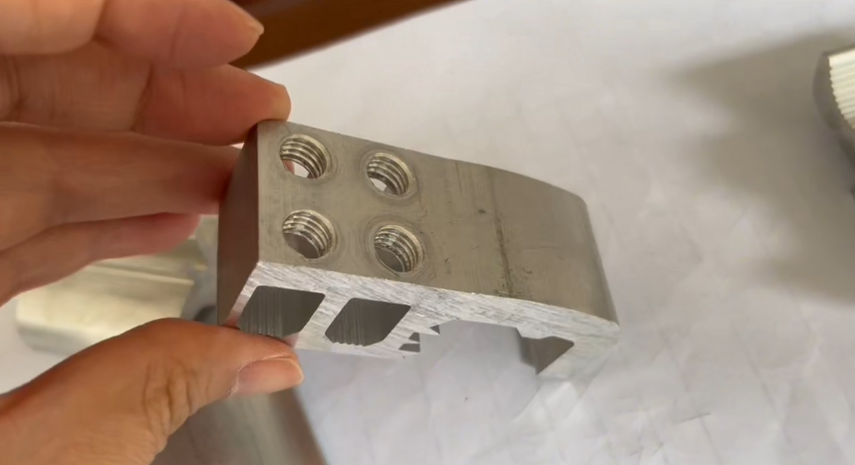

Automatic drilling module: realizes multi-point fast drilling and precise positioning;

Automatic tapping unit: seamlessly connected with drilling, automatically completes thread processing;

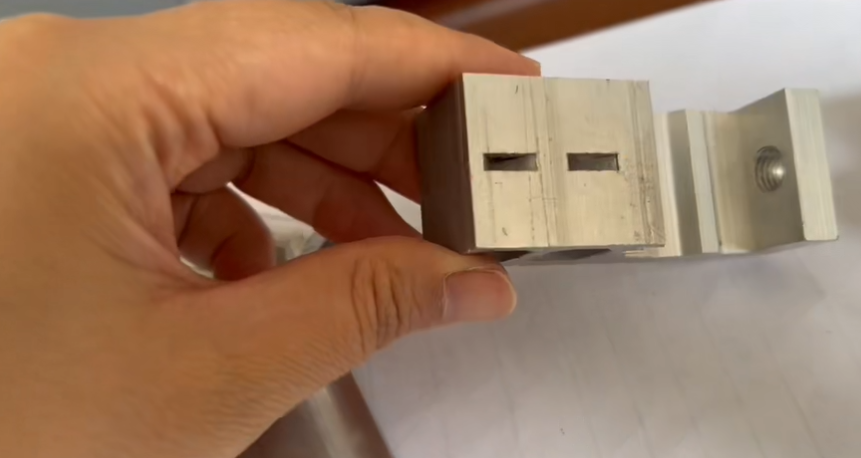

Punching system: structurally sound to ensure consistent stamping every time;

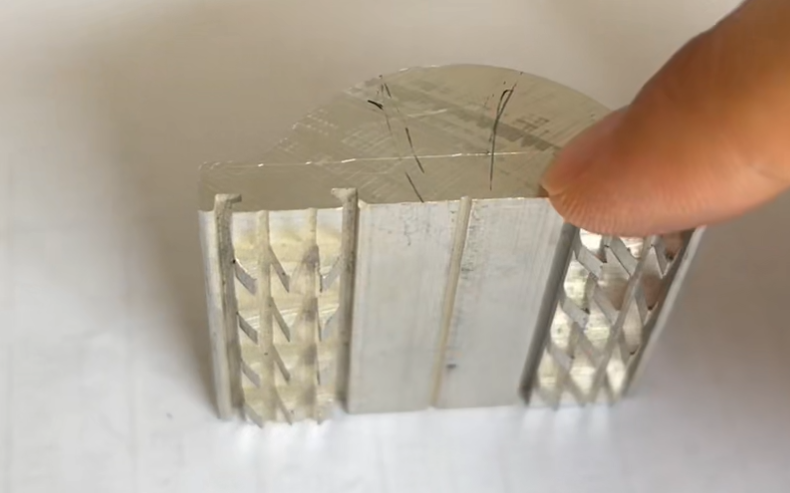

High precision slotting device: supports multiple adjustable specifications to meet different product processing needs.

The entire device supports programmatic control, and multiple steps of continuous processing can be completed with just one click, greatly reducing manual intervention and improving production efficiency and safety.

Multi functional integration, saving space and labor costs

In the traditional production mode, drilling, tapping, stamping, and slotting often need to be carried out step by step in different processes or machines, which not only occupies a lot of space but also increases the risk of manual handling and alignment errors. The customized non-standard automation equipment adopts a modular integrated structure, where multiple processing steps are continuously completed in one device. The overall structure is compact and easy to deploy in existing factory environments.

The customer conducted a series of tests on the equipment during the trial production phase and provided feedback that its daily production capacity increased by over 60%, significantly reducing the labor intensity of operators and meeting its expected automation upgrade goals.

International cooperation continues to deepen, and the delivery capability of non-standard projects is further upgraded

As a professional enterprise engaged in the research and manufacturing of automation equipment, our company has provided customized solutions for customers in multiple countries and regions, covering industries such as power hardware, photovoltaic brackets, automotive parts, aluminum profiles, rubber and silicone products, etc.

The smooth delivery of this Russian project not only demonstrates our company's technical strength in the field of non-standard equipment, but also further promotes the deep cooperation between China and Russia in the field of industrial automation. In the future, we will continue to be customer-oriented, providing more efficient, intelligent, and flexible automation equipment to help global customers achieve production line upgrades and intelligent manufacturing.

Customer reviews and follow-up services

After the delivery of the equipment and completion of on-site remote guidance and debugging, the Russian customer gave high praise: "This equipment fully meets our design requirements, runs very smoothly, and has significantly improved efficiency. We will discuss more project cooperation with your company in the future

Our company has also equipped the equipment with a remote monitoring and technical support system to ensure that any technical issues that arise during the customer's subsequent use can be responded to and resolved in a timely manner.