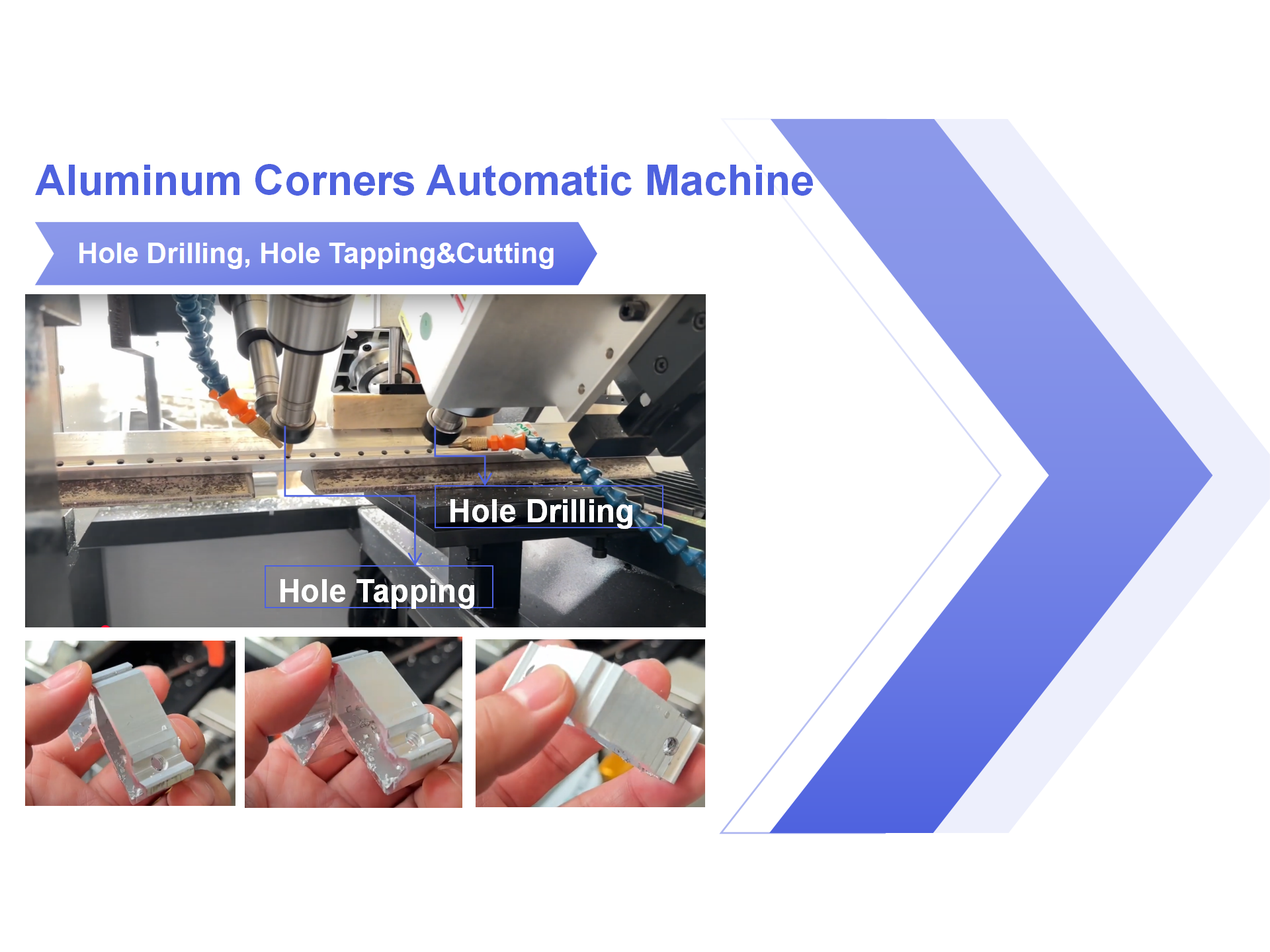

Integrated drilling, tapping, and cutting!

>Efficient and precise automation equipment is reshaping the new landscape of the aluminum alloy processing industry.

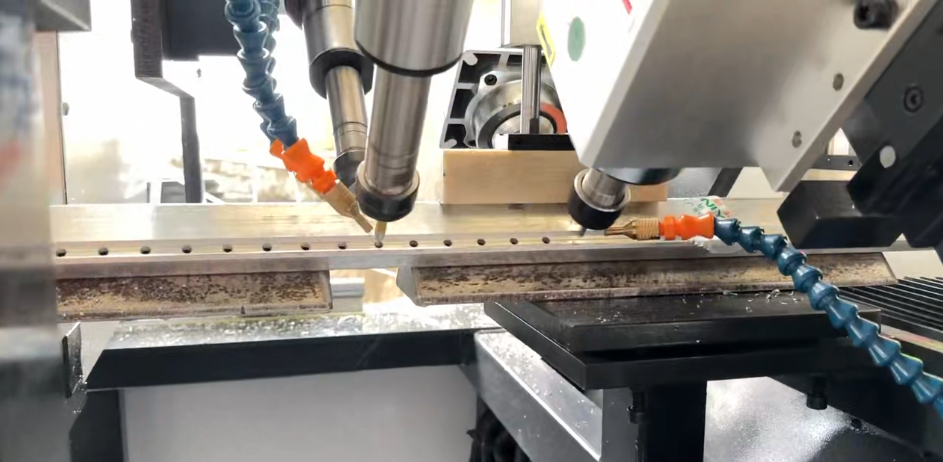

Accompanied by rhythmic mechanical sounds, precise length corner codes are produced like a flowing stream, and workers only need to collect, organize, and cut the completed corner codes at regular intervals.

This set of non-standard customized equipment realizes the full process automation from feeding, positioning to cutting, with a single shift output exceeding 30000 units and precision controlled within 0.1 millimeters. This customized production line for customers integrates drilling, tapping, and cutting functions, * * solving the pain points of scattered equipment and low efficiency in traditional corner code processing * *.

##01 Technological breakthrough, creating a new benchmark in the industry

The automated corner code processing system put into operation this time represents the advanced level of domestic aluminum processing equipment. This system integrates multiple technological innovations and provides a full process solution for door and window manufacturing enterprises.

The equipment feed system is driven by a combination of ball screws and gas-liquid damping cylinders, and runs smoothly on linear guides to achieve precise control of cutting feed and rapid retraction. This design avoids the crawling phenomenon of traditional pneumatic systems and ensures the size consistency of each product.

##02 Customer value, visible improvement in efficiency

For customers, the launch of this automated production line has brought significant benefits. The most direct change comes from the transformation and upgrading of production modes.

**Traditional corner code processing requires multiple equipment and personnel to operate, but now only one operator is needed to manage the entire production line. Our production manager calculated that cutting corner codes by oneself reduces costs by more than 40% compared to purchasing ready-made corner codes. Based on the annual consumption of 2 million corner codes, this alone can save material costs of over one million yuan per year.

The efficiency improvement is even more astonishing. This device can cut 16-24 corner codes at a time, with a daily output of over 30000 pieces, which is more than four times more efficient than traditional corner code cutting machines.

The improvement of processing accuracy is directly reflected in product quality. The equipment is equipped with a spindle accuracy of 0.01mm, ensuring stable control of aluminum corner code cutting accuracy within 0.1mm, completely solving the common size deviation problem of traditional equipment.

The special advantage of this device is also reflected in the material utilization rate. By configuring a 2.5mm ultra-thin saw blade and an intelligent tail material control system, material waste is minimized to the greatest extent possible. The technician said, "Previously, the tail material loss rate for cutting corner codes was around 5%. The new equipment uses intelligent sizing function to control the tail material within 1%

##03 Service guarantee, full cycle solution

As a professional expert in customized non-standard automated aluminum processing equipment, we not only provide high-performance equipment, but also build a service system that covers the entire lifecycle of the equipment.

In the early stage of cooperation, * * analyzed the bottleneck of the production process * * and tailored this multifunctional production line to its characteristics of multiple corner code specifications and large order fluctuations. This device adopts a modular design and can flexibly adjust its functional configuration according to customer needs, meeting the production needs of doors and windows enterprises of different scales.

We strictly adhere to the quality commitment of "one-year equipment warranty and two-year main component warranty" and provide lifelong maintenance services. Outside the warranty period, only cost fees will be charged.

The service guarantee system includes:

-* * Free debugging of equipment and training of operators * * to ensure customers quickly master equipment operation skills

-Regular * * follow-up maintenance services * * to prevent equipment failures from occurring

-Fault diagnosis hotline support, * * rapid response mechanism * * to ensure timely recovery of the production line

-Provide original cost price accessories to avoid customers using inferior parts that may cause equipment damage

We also provide value-added services to customers, including factory floor plan design, personnel configuration optimization suggestions, and even provide information on raw material suppliers and market analysis to help customers enhance their competitiveness in all aspects.