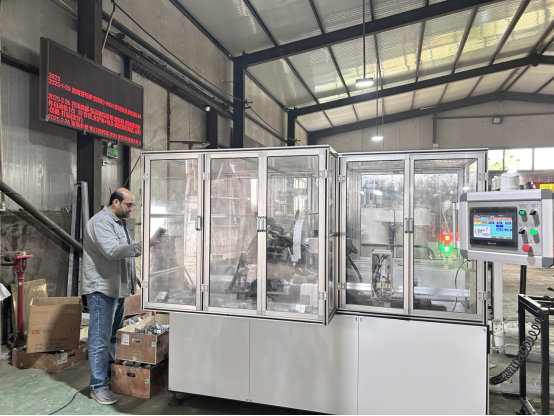

Israeli client visits our company for inspection and operation training of corner code automatic machine

Deepen cooperation and seek common development - International customers highly recognize our company's intelligent manufacturing strength

In late May 2025, our company welcomed a delegation of important cooperative customer representatives from Israel. The main focus of this visit is to conduct on-site inspection of the customized corner code automatic machine purchased by the customer before leaving the factory. At the same time, a two-day systematic training and exchange will be conducted on the actual operation, maintenance, technical details, and after-sales service of the equipment.

The customer's purchase of our corner code automatic machine this time is not only a recognition of our product strength, but also reflects the continuous deepening of technical exchanges and manufacturing cooperation between China and Israel.

On site inspection: strict quality control, pursuit of perfection in every detail

After the customer arrived at our company, our sales manager and technical director first accompanied the customer to visit the production workshop and assembly workshop. The customer highly recognizes our company's production environment, workshop layout, process arrangement, and quality control process, and gives positive evaluations to our employees' operating standards, on-site management, and production efficiency.

Subsequently, the customer enters the inspection process and conducts a comprehensive inspection of the purchased corner code automatic machine. The inspection content covers the following aspects:

Appearance quality: The customer inspected the details of the equipment casing, structural components, spray treatment, fasteners, etc., and confirmed that there were no scratches, paint peeling, or other issues. The overall appearance of the equipment is finely crafted and fully meets the requirements of the order.

Core component verification: The customer focused on verifying and conducting functional tests on key components such as the feeding mechanism, corner code pressing system, PLC control unit, electrical components, pneumatic system, etc., to ensure consistency with the configuration specified in the contract.

Operational testing: Our technical engineers conducted on-site demonstrations and operations of the equipment. The whole machine starts smoothly, the feeding is precise, the pressing force is moderate, and each link runs smoothly. The customer observed and personally operated the entire process, and expressed great satisfaction with the efficiency and stability of the equipment.

Document verification: Our company has prepared complete equipment technical manuals, operation manuals, maintenance guides, circuit drawings, and equipment certificates for the customer. After the customer confirms each item, they sign and accept them.

After the inspection was completed, the customer expressed, "We highly recognize your company's manufacturing capabilities and quality management system. The entire equipment is designed, manufactured, and assembled with professionalism and refinement, especially your team's diligence and patience in equipment debugging, which makes us more confident in putting it into use

Professional training: Systematic learning and operation to assist customers in worry free production

After the inspection, in order to ensure that the customer can install, use, and maintain the equipment smoothly, our company arranged a two-day operation and technical training for the customer. The training is led by a senior engineer from our engineering technology department, covering various aspects such as equipment construction principles, operating procedures, safety precautions, daily maintenance, and common fault handling.

1. Theoretical explanation and structural analysis

The first stage of the training is theoretical course explanation, which combines PPT and physical equipment to provide a detailed introduction to the overall architecture, functional modules, control system, and working principle of the corner code automaton. The customer is particularly concerned about the following key technical points:

How to ensure compatibility of different size corner codes in the automatic feeding system;

The adaptability of the press fit mechanism to workpieces made of different materials;

The logical relationship between each control unit in the PLC program;

How to achieve maximum efficiency in automated operation of the entire machine.

Through the engineer's easy to understand explanation, the customer gained a comprehensive understanding of the system composition and functional implementation of the diagonal code automaton, laying a solid foundation for practical operation.

2. Practical exercises and on-site simulated production

The second stage of training is arranged in the equipment debugging area, where engineers provide one-on-one guidance to customers on practical operations such as equipment startup, debugging, workpiece clamping, parameter setting, and alarm handling. The customer gradually completed the entire process from start-up, calibration to production and processing.

Especially in simulating real production conditions, customers personally operate by installing multiple different corner code products, understanding the equipment's automatic adjustment ability for precision control, pressing speed, and clamping force, and independently completing operation settings based on workpiece transformation parameters. Throughout the process, the client demonstrated a high level of learning enthusiasm and professional competence, ultimately mastering the standard operating procedures of the equipment proficiently.

3. Maintain knowledge and troubleshoot

The final part of the training focuses on explaining the daily maintenance and troubleshooting methods of the equipment. This includes emergency response plans for gas source management, electrical inspection, lubrication system maintenance, replacement cycles for vulnerable parts, and typical issues such as material jamming, false alarms, positioning deviations, etc. The customer stated that this section is highly practical and provides a guarantee for the long-term operation of the equipment in the Israeli factory in the future.

Customer feedback: Looking forward to deeper cooperation and promotion

After the successful completion of the training and inspection, the client held a brief discussion with our company to summarize and provide feedback on the visit