PV Clamp Automatic Machine

Automated forming with controllable precision

Adopting servo/pneumatic drive systems, it can accurately perform bending and stamping forming according to the dimensional parameters of clamps of different specifications (mainly aluminum alloy). The forming tolerance can be controlled within ±0.1~0.3mm, meeting the tight fit requirements of PV mounting brackets and modules.

Multi-specification compatibility and quick mold change

It supports production switching of various types of clamps (e.g., Type 30, Type 40, Type 50), with a short mold change time (usually 5~15 minutes), adapting to the installation needs of PV modules of different power ratings.

High-efficiency continuous production

It can be connected with coil or profile raw materials to realize integrated operations of feeding → forming → cutting → discharging. The production capacity of a single machine can reach 300~800 pieces per hour, greatly improving production efficiency.

Intelligent inspection with low defective rate

Equipped with visual or sensor inspection modules, it can real-time monitor clamp dimensions and forming angles, automatically reject unqualified products, and the yield rate can reach over 99.5%.

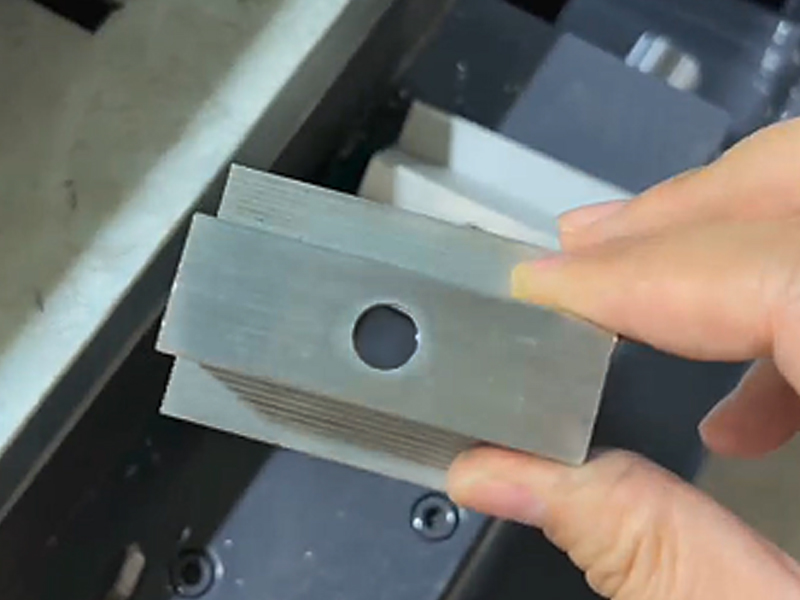

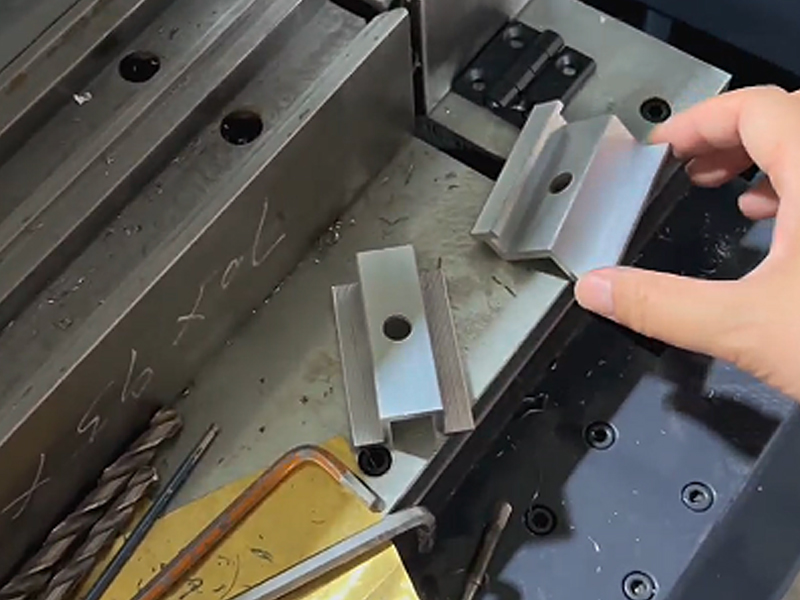

Solar Photovoltaic Aluminum Machine Sample Display

Main Applications

It is used for manufacturing PV mounting clamps, which are core accessories for fixing the borders of PV modules to guide rails. They are widely applied in the mounting system installation of ground-mounted PV power plants and distributed rooftop PV projects.

It is suitable for processing clamps made of different materials such as aluminum alloy and stainless steel, meeting the corrosion resistance and compression resistance requirements in different environments like coastal areas and high-altitude regions.

PV Punching & Cutting Automatic Machine

Integrated punching and cutting functions

It combines two core processes of punching (for mounting holes, positioning holes) and cutting (for length fixed-length cutting) in one machine, eliminating the need for multiple equipment transfers and reducing intermediate process errors.

High precision and stable performance

The punching part adopts precision mold positioning, with hole position accuracy up to ±0.2mm; the cutting part uses a high-speed saw blade or shearing structure, with a cutting surface flat and burr-free, meeting the precision requirements of PV bracket assembly.

Flexible parameter setting

It supports customized setting of punching positions, hole diameters and cutting lengths through the touch screen, adapting to the processing needs of PV bracket profiles of different specifications (e.g., aluminum profiles, steel profiles).

Safety and reliability

Equipped with safety protection devices such as protective covers and emergency stop buttons, it meets industrial safety standards and prevents operator safety accidents during high-speed operation.

Solar Photovoltaic Aluminum Machine Sample Display

Usmart-Your Aluminum Automatic Machine Customized Expert, Contact Us Today:

WhatsApp/Wechat:+86-19819888691 WA:https://wa.me/8619819888691

Email:info@usmartcnc.com Website: https://www.usmartcnc.com

Youtube:https://www.youtube.com/@usmartaluminummachine

Tiktok:https://www.tiktok.com/@aluminummachine

Facebook:https://www.facebook.com/profile.php?id=61582053957512